Microcracking Mechanisms of Granite

Cracking behavior of granite under tensile loading: insights from thin-section analysis

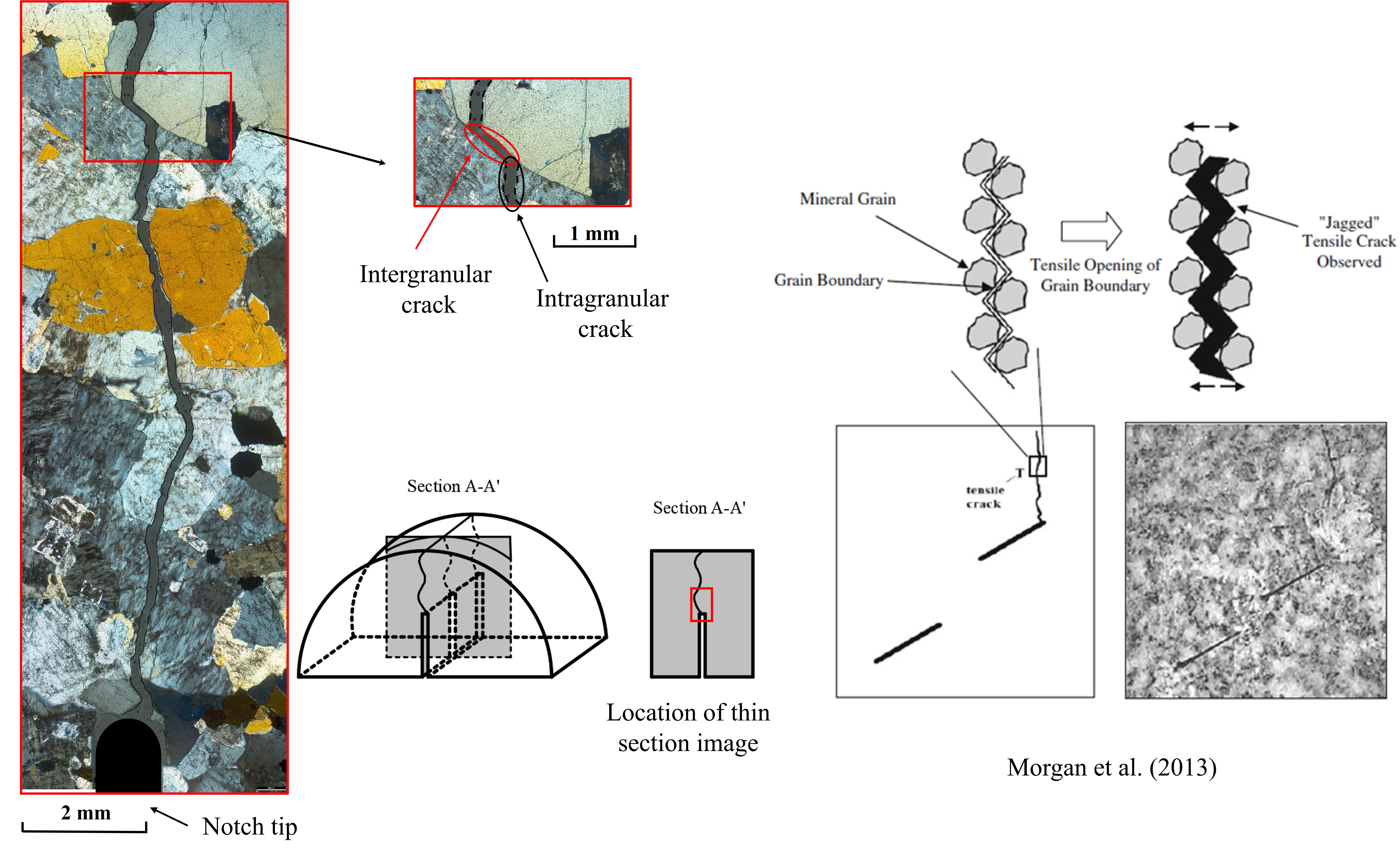

By analyzing the thin section of macrocracks induced in semi-circular bending (SCB) tests, we demonstrated that the tortuous tensile-induced cracks in granite predominantly propagate through grains rather than along grain boundaries [1]. This conclusion challenges the prevailing view in the field that tortuous tensile cracks propagate along grain boundary in granite, offering new insights into the cracking mechanisms of granite.

Thin section images showing the tensile cracks in the SCB specimen (left) and the conceptual model of tensile cracks proposed in Morgan et al. (2013) (right).

Microcracking behavior transition in thermally treated granite

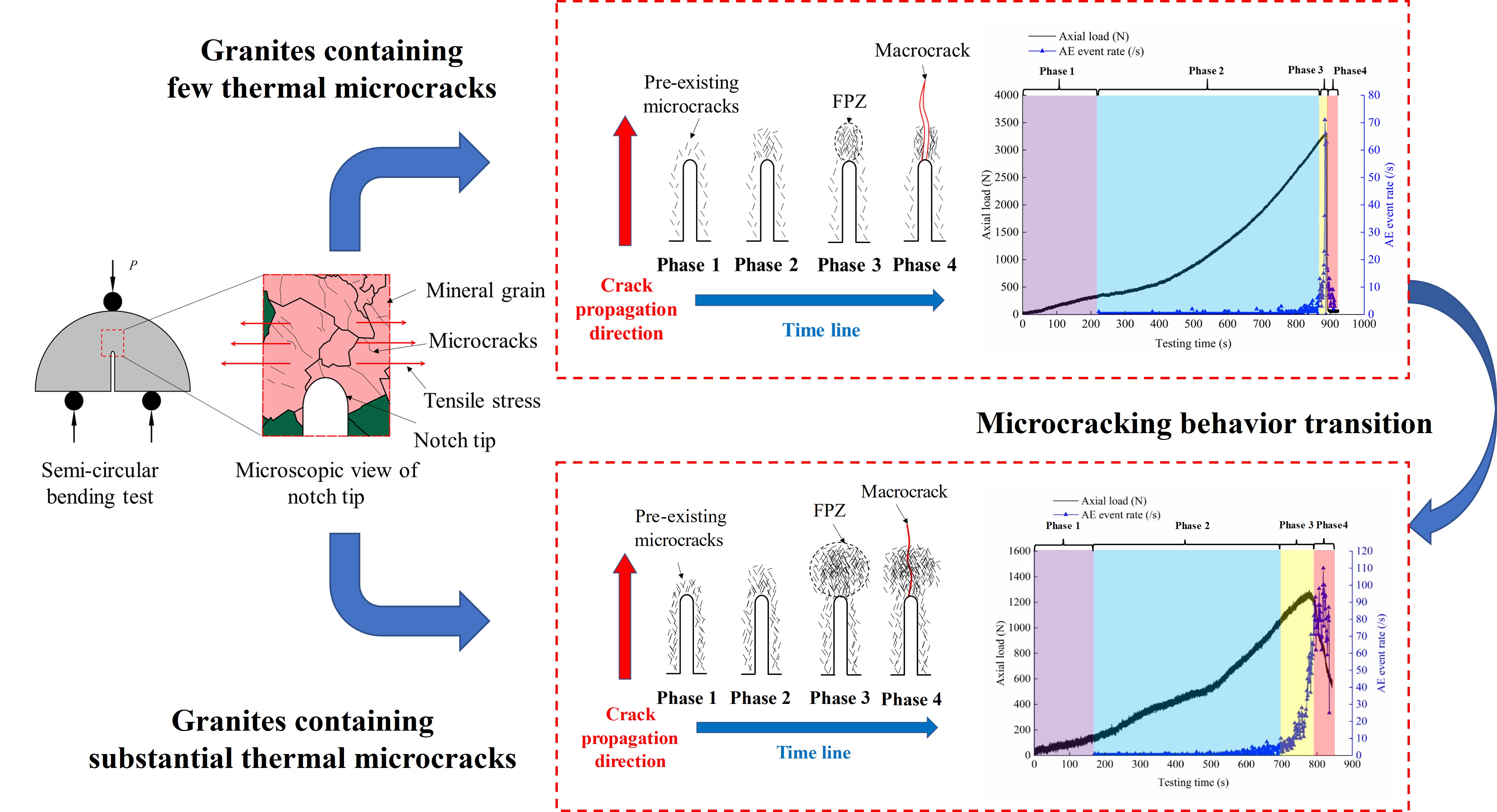

We identified the microcracking behavior transition in thermally treated granite and proposed an extended conceptual model to describe the fracture process zone (FPZ) evolution prior to unstable fracture propagation in crystalline rocks [2]. For the crystalline rocks with relatively small numbers of pre-existing (thermal) microcracks, as the tensile stress applied to a macroscopic fracture increases, the FPZ does not significantly develop until the load reaches a relatively high level approaching the failure load. In contrast, for the granite with more pre-existing (thermal) microcracks, the FPZ actively develops at the load level much lower than that in the former case. In addition, the duration of FPZ development is longer for the granite with more pre-existing microcracks. Since more microcracks are reactivated in the latter case, the FPZ is characterized by larger size and higher microcrack density at the moment when the macroscopic crack initiates.

An extended conceptual model describing the FPZ evolution before unstable fracture propagation in crystalline rocks.

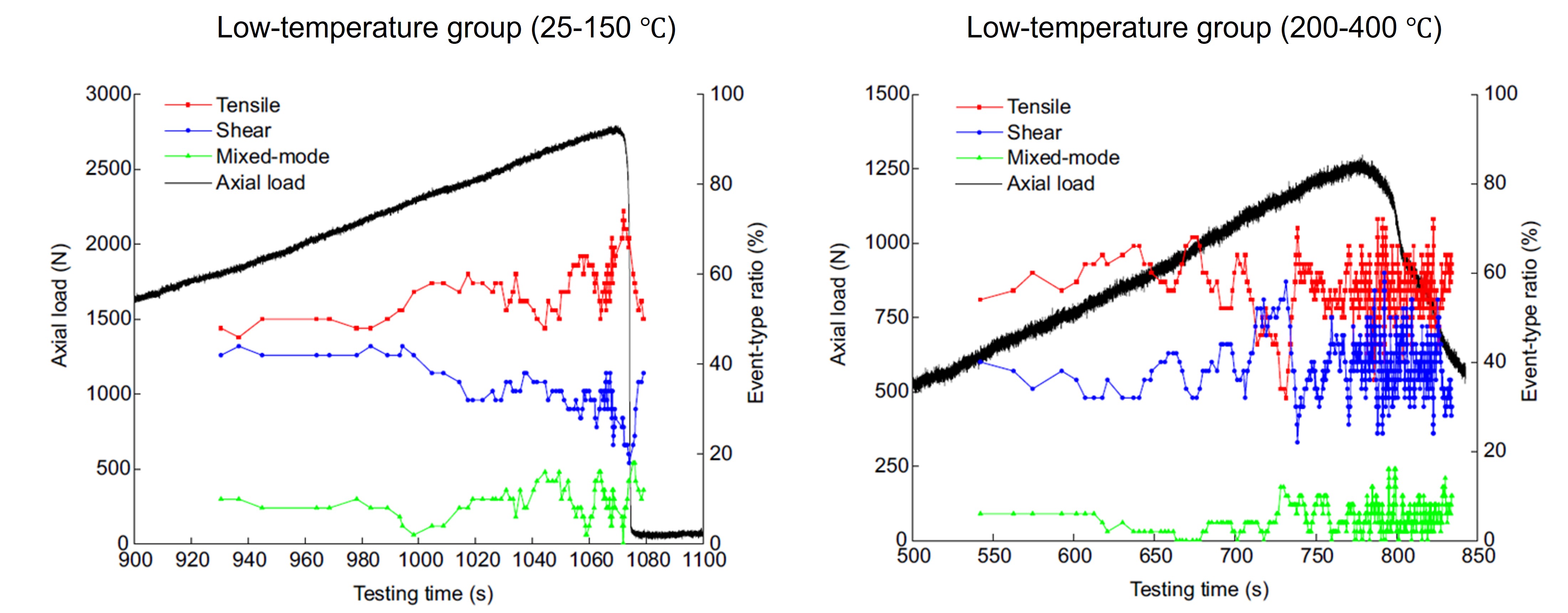

The temporal evolution features of the event-type ratio are different between the specimens with fewer pre-existing thermal microcracks and those with substantial pre-existing thermal microcracks. For the former, the tensile event ratio rapidly increases to its peak, while the shear and mixed-mode event ratio decreases, which becomes a precursor preceding the initiation of macrocracks, while this precursor becomes invisible for the latter [3].

The typical temporal changes of axial load and event-type ratios for straight-through notch SCB specimens after the (left) low-temperature (50 ◦C, 100 ◦C, 150 ◦C) and (right) high-temperature (200 ◦C, 400 ◦C).

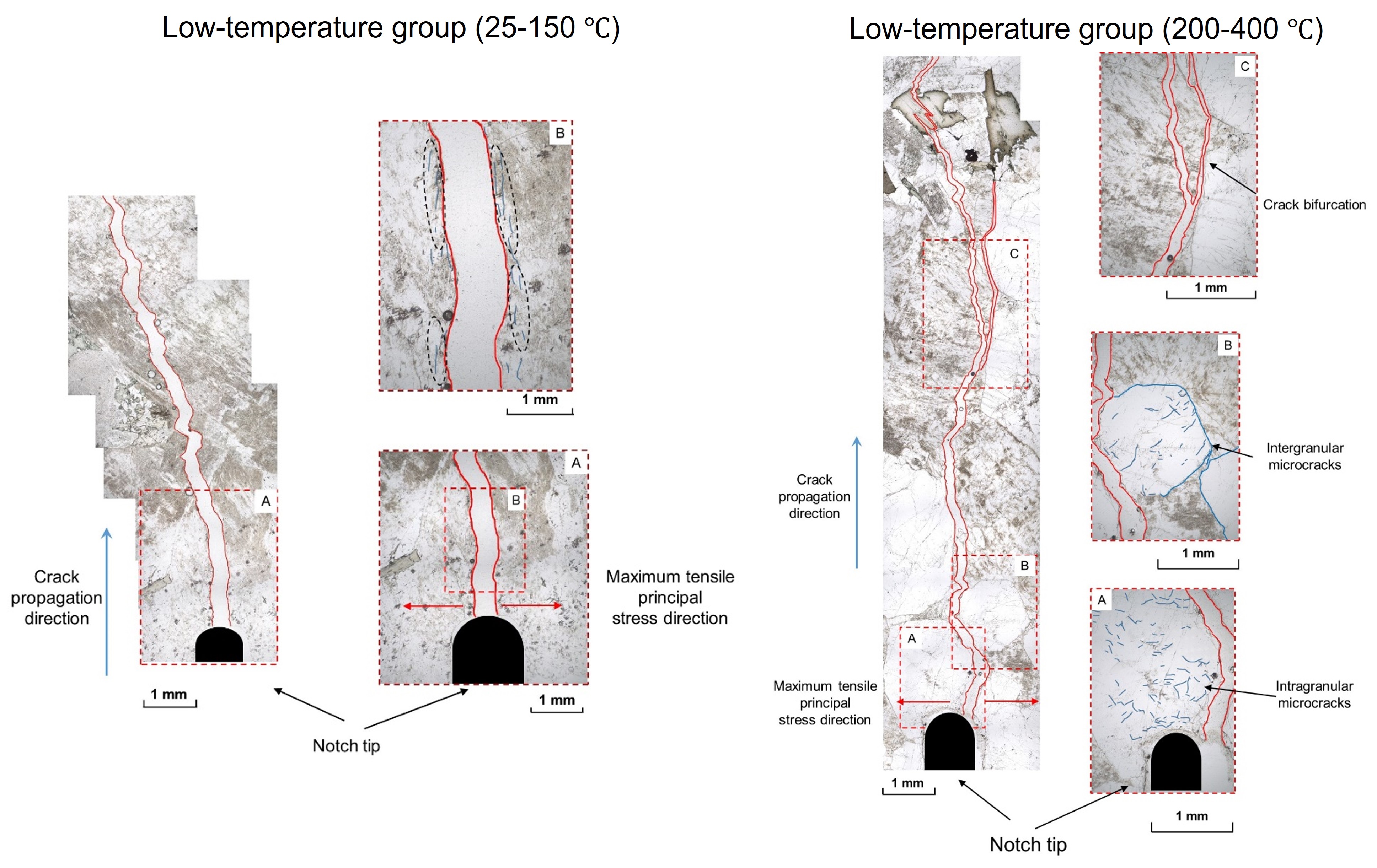

To explain the differences in the temporal evolution features of the event-type ratio, we conducted thin-section analysis on tensile cracks induced in the straight-through notch SCB specimens after thermal treatment at different temperatures thermal treatments. Given that the thermally induced pre-existing microcracks do not have a strong preferred orientation, the event type would vary with the inclination angles between the microcracks and the maximum tensile stress direction. Therefore, all three event types could be observed during the tests. For the new tensile fractures which generally develop coplanar with the pre-existing notch plane, the displacement of their walls is approximately normal to the tensile stress, which tends to mainly produce the tensile events. The competition between these two mechanisms accounts for the variations of event-type ratios during the microcracking process [3].

Thin-section images showing the typical microscopic features of tensile cracks induced in the straigh-tthrough notchSCB specimens after the (left) low-temperature (50 ◦C, 100 ◦C, 150 ◦C) and (right) high-temperature (200 ◦C, 400 ◦C) thermal treatments.

Fracture process zone (FPZ) of granite in mode I SCB tests

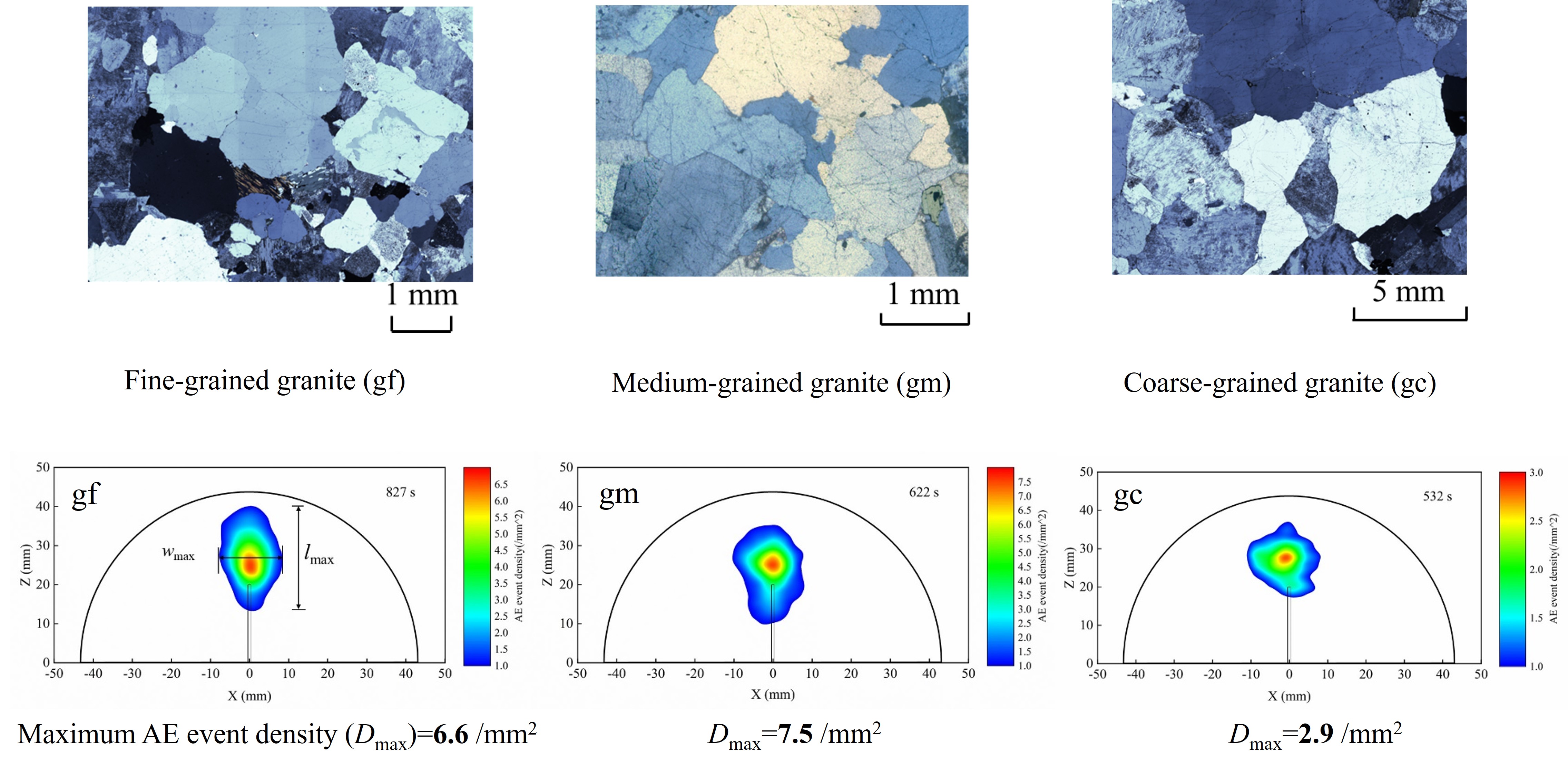

We investigated the effects of mineralogy and texture on the microcracking behavior of granites under mode I loading [4]. The studied three granites show distinct AE event spatial evolution features during the microcrack development period, which results in different AE event distributions. This difference is attributed to the distince grain size and mineralogy of the three granites. The AE event density contour shapes of the fully-developed fracture process zone are generally elliptical for the fine-grain granite. As the grain size of the studied granites increases, the contours become more irregularly-shaped. The medium-grain granite with the most pre-existing microcracks has the largest maximum AE event density.

Thin-section images (upper) and AE event density contour of fully-developed FPZ (lower) of straight-through notch SCB specimens with different grain sizes.

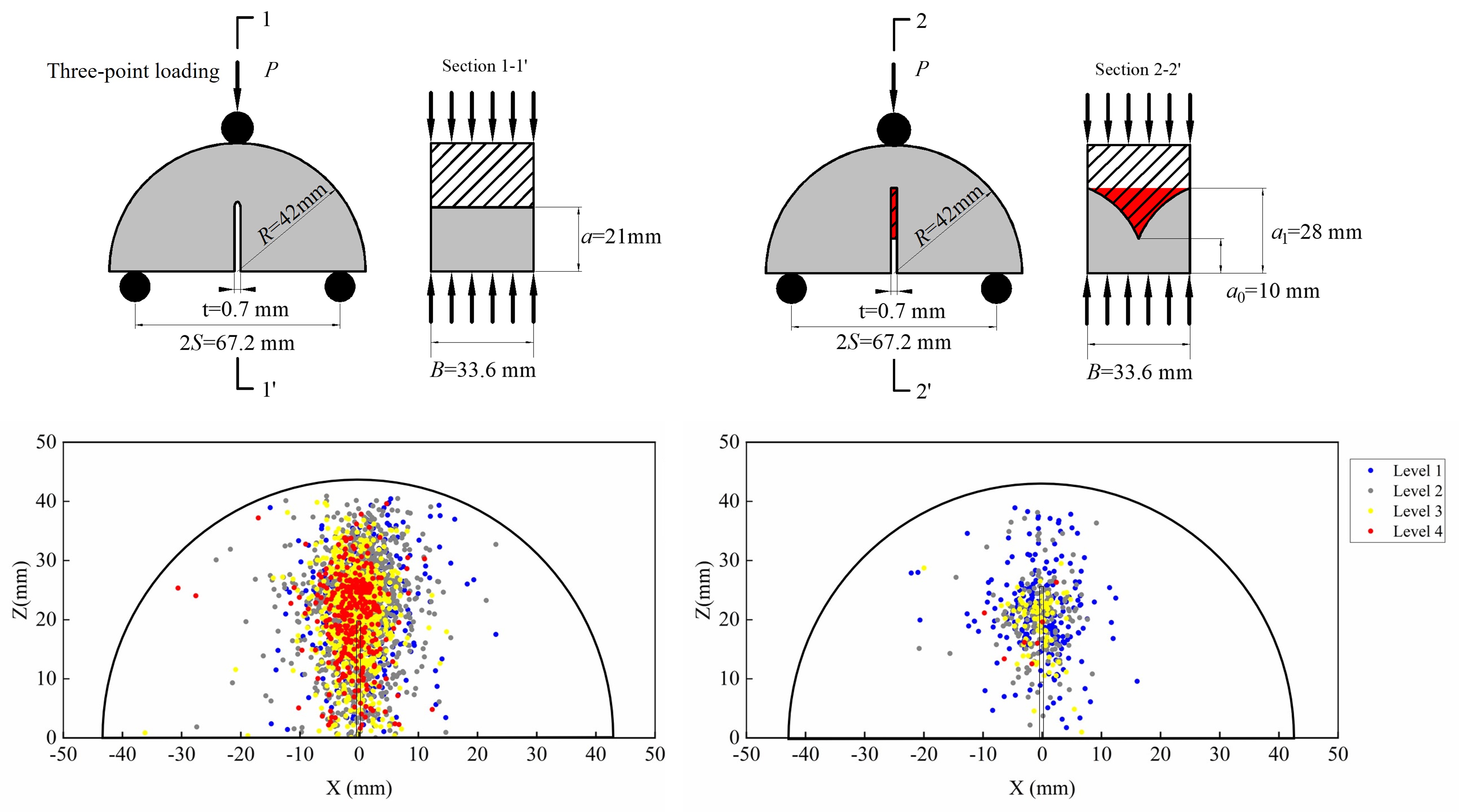

We investigated the effects of pre-cut notch shape (straight-through vs chevron) on the FPZ features in semi-circular bend (SCB) granite specimens under mode I or tensile loading [5]. The SCB test is one of the suggested methods to measure the fracture toughness of rocks. Analysis of AE data reveals a relatively larger FPZ in specimens with a straight-through notch as compared with those with a chevron notch. This finding explains the discrepancy in the fracture toughness measured using SCB specimens with different notch shapes.

AE event scatter of the fully-developed FPZ of SCB specimen with straight-through (left) and chevron (right) notch.

References:

[1] Wong L.N.Y., Guo T.Y.*, Lam W.K., & Ng J.Y.H. (2019). Experimental study of cracking characteristics of Kowloon granite based on three mode I fracture toughness methods Rock Mechanics and Rock Engineering.. 52(11), 4217-4235. https://doi.org/10.1007/s00603-019-01882-w

[2] Guo T.Y., Wong L.N.Y.*, & Wu Z. (2021). Microcracking behavior transition in thermally treated granite under mode I loading. Engineering Geology. 282, 105992. https://doi.org/10.1016/j.enggeo.2021.105992

[3] Wong L.N.Y., Guo T.Y.*, Wu Z., & Xiao X. (2021). How do thermally induced microcracks alter microcracking mechanisms in granite? Engineering Geology. 292, 106268. https://doi.org/10.1016/j.enggeo.2021.106268

[4] Guo T.Y., & Wong L.N.Y.* (2020). Microcracking behavior of three granites under mode I loading: Insights from acoustic emission. Engineering Geology. 278, 105823. https://doi.org/10.1016/j.enggeo.2020.105823

[5] Wong L.N.Y., & Guo T.Y.* (2019). Microcracking behavior of two semi-circular bend specimens in mode I fracture toughness test of granite Engineering Fracture Mechanics. 221, 106565. https://doi.org/10.1016/j.engfracmech.2019.106565